Quality

- Home

- Quality

The surface finish and coating of fasteners are critical for corrosion resistance and aesthetic appeal. QA in this area involves checking the thickness, adhesion, and uniformity of coatings, such as zinc plating or galvanization.

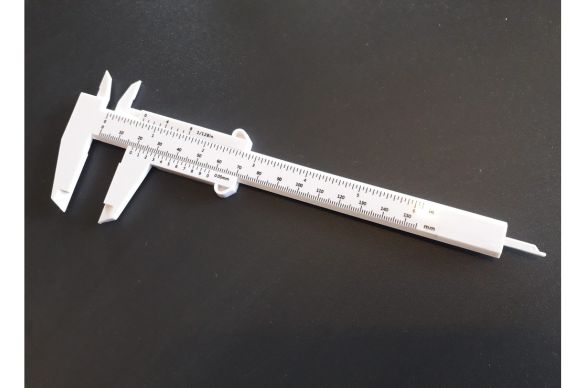

Fasteners must meet precise dimensional specifications to ensure proper fit and functionality. QA processes include measuring critical dimensions such as diameter, length, thread pitch, and head shape to verify compliance with standards.

Quality Assurance in fasteners ensures the precision and reliability of mechanical connections, meeting industry standards for strength and durability.

Ensuring that the materials used in fastener production meet specified standards in terms of composition, strength, and durability.Tracking and documenting the source of raw materials to maintain accountability and facilitate any necessary recalls.

Measuring the fasteners to verify compliance with specified dimensions, including length, diameter, thread pitch, and head size. Ensuring that the fasteners fall within acceptable tolerances to guarantee proper fit and functionality.

Ensuring precision and durability, quality control in brass fasteners maintains standards of reliability in every bolt and screw.

Quality control in fasteners is a crucial aspect of manufacturing and production processes to ensure that these small yet vital components meet the required standards and specifications. Fasteners play a significant role in various industries, including automotive, aerospace, construction, and electronics.

The primary function of the machine is to subject fasteners to tension until failure occurs. This helps in determining various mechanical properties such as ultimate tensile strength, yield strength, elongation, and modulus of elasticity.

Fastener tensile testing machines come in a range of load capacities to accommodate different sizes and types of fasteners. They can handle loads ranging from a few pounds to several tons, depending on the application requirements.

The machine typically includes specialized fixtures and grips designed to securely hold the fastener during testing.

This equipment is equipped with grips and fixtures to apply tensile loads to fasteners, measuring their tensile strength, ultimate tensile strength, yield strength, and elongation.

Some machines are capable of conducting compression tests on fasteners to determine their compressive strength and behavior under compressive loads.

Torque testing equipment measures the rotational force required to tighten or loosen fasteners, providing insights into their torque characteristics and performance.

This equipment includes hardness testers such as Rockwell, Brinell, or Vickers testers to assess the hardness of fastener materials, which is crucial for determining their resistance to deformation and wear.

At GR Fasteners, we believe in securing your success - connect with us for unparalleled quality and reliability in every fastener, ensuring your projects hold together with excellence.